Shaping a More Efficient Construction Industry

The construction industry is one of the most resource intense industries, with very low productivity increases per year. But there are many opportunities to catch up using innovative digital solutions. With targeted investments in startups, the Nemetschek Group aims to accelerate the market launch of innovative products, one example is the Norwegian deep tech company Imerso.

Author

Tilman Köberlein

After studying business administration in Mannheim (BSc) and Oslo (MSc), Tilman Köberlein initially managed HeidelbergCement's cargo ship fleet in Northern Europe for six years before moving to the management of Imerso in 2019. Imerso's software makes it easy to capture 3D Scan data (point clouds) and uses them for an automatic comparison with the BIM models.

This article belongs to the collection Quality & Efficiency

To the topic pageThe construction industry's digital transformation has gained significant momentum in recent years. The fact that the digitalization curve is pointing upwards is not only due to the COVID- pandemic and a generally increasing interest in digitalization topics, but above all to the convincing added values that can be achieved along the entire value chain with the help of digital tools. These include, for example, better overall planning of projects and the associated resources, increased cost, and schedule reliability, faster coordination loops through paperless processes, and stringent quality assurance across all project phases.

Connecting Industry Knowhow to Entrepreneurship

Startups are a key driver of innovative solutions for a more efficient construction industry. Imerso, founded in 2015, offers a platform for automating quality control and monitoring with the help of artificial intelligence, reality Capture and BIM technologies.

Imerso makes the use of industrial-grade 3D scanners directly on the construction site as easy as taking a picture. In doing so, these scanners capture the as-built condition throughout the construction phase generating point clouds that accurately capture a room, building or floor, for example. Imerso's cloud platform then automatically analyzes this captured data and compares it with the BIM model. This allows deviations or problems to be highlighted in real-time - and changes can be made before they jeopardize the progress of a project. This direct link between BIM and the as-built condition on the construction site creates accurate digital twins using Imerso, which benefits the entire lifecycle of a building. In addition, the combination of the technologies of the Nemetschek Group brand Solibri and Imerso enables significant opportunities for builders, engineers and contractors, not only during the construction phase, but also before, and later in building management.

Massively increased efficiency

Two use cases show how Imerso can bring greater efficiency to construction sites

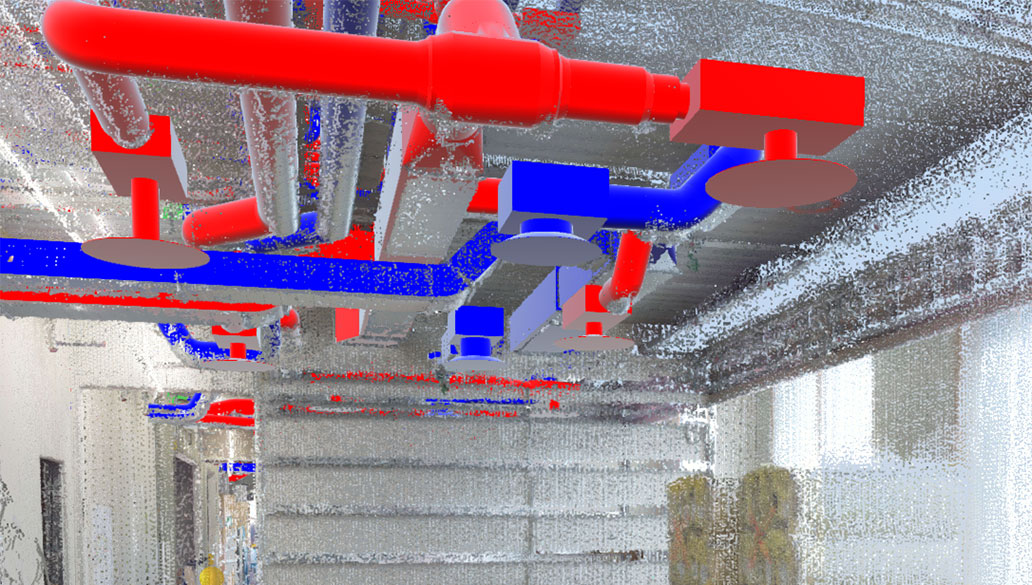

E. Klink, a Danish HVAC (heating, ventilation, and air conditioning) company and part of the Aarsleff Group of companies, is a pioneer in the field of creating and maintaining energy-optimized ventilation systems. To ensure consistently high quality in the planning phase, E. Klink has been using Solibri for BIM quality checking since 2017. In 2019, the company launched a broader ‘Digital design with 3D’ initiative However, during the actual construction phase, the quality control of the piping systems and ventilation systems was still done randomly and analogously. This meant that only a small part of the entire project was covered and there was a risk of overlooking problems. In September 2021, E. Klink decided to use Imerso's software solution to support quality control throughout the production phase. After just two months, the results are impressive: the E. Klink team was able to inspect 100 percent of the ducts and ventilation systems within the same time it used to take to inspect only 15 to 20 percent. This represents a productivity increase of over 400 percent. In addition to increasing efficiency throughout the production process, E. Klink also avoids unforeseen delays during the production phase and, by documenting the work to the millimeter, reduces the risk of warranty claims after the project is completed.

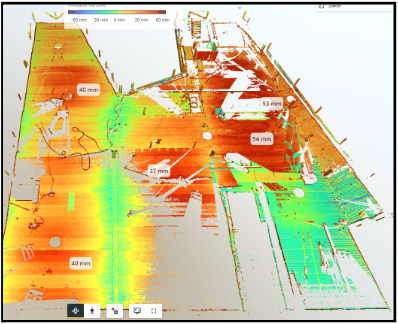

At Betonmast, a Norwegian construction company, the increase in efficiency by using Imerso was even higher. Betonmast builds turnkey residential and commercial buildings; one of the critical parts is the installation of precast concrete elements. There, tight contractual tolerances apply in terms of building height, angles, and cracks. If errors are overlooked, the consequences are often costly. Not only do replacements have to be procured, but the project is often delayed due to rework which can lead to a daily fine of one per mille of the contract sum. In the past, the company used a combination of checklists, spot checks and manual surveys for quality control in areas where these methods are possible. However, this process was very time-consuming: only 10-15% of areas could be inspected this way. An alternative was needed: after testing several solutions, the choice fell on Imerso's platform in combination with a laser scanner. The platform automatically compares the actual state on-site, represented by the 3D scans, with the specifications of the construction plans in the BIM model. Discrepancies that can lead to costly consequences are quickly detected and rework can be carried out immediately. The company now inspects and documents 100% of the relevant areas in the same amount of time that it previously took to capture about 15% through sampling – in sum a productivity increase of over 500%. In addition, this proactive approach prevents unplanned downtime, contract penalties, or the need to reschedule later in the project.

For More Efficiency in Construction

These examples show how innovative startups like Imerso can drive the digitalization of the construction industry and that the combination of established industry know-how and entrepreneurial spirit is a perfect fit for shaping the future AEC/O market and driving innovation. It is the only way forward, as the complexity of large-scale projects is increasing rapidly. Whereas in the past it was still possible to build on greenfield sites, today new buildings often must fit into existing, already-built environments. At the same time, the number of people involved in the construction process is growing. Digitalization can take place in individual work steps or, ideally, holistically across the entire construction lifecycle – from planning through the design and construction phases to building operation. A greater efficiency, enabling new ways of working, increasing sustainability – the benefits and the impact of digital tools are huge. Ultimately, they are the asset to shape a better world.