Kewazo’s robots make construction sites safer and more efficient—with support from the Nemetschek Group, which has been an investor since 2023.

Solving the Skills Shortage Through Innovation and Robotics

Author

Artem Kuchukov

Co-Founder & CEO KEWAZO

This article belongs to the collection Innovation.

To the topic pageThe construction industry faces an unprecedented labor shortage as skilled workers retire faster than they can be replaced and fewer young people enter the field. Combined with thin profit margins, companies cannot rely on higher wages alone to attract talent. To remain competitive, the industry must embrace innovation and technology. Robotics and automation can enhance efficiency, improve safety, and create more attractive working conditions, helping to close the labor gap while maintaining profitability.

The Role of Technology in Addressing Workforce Challenges

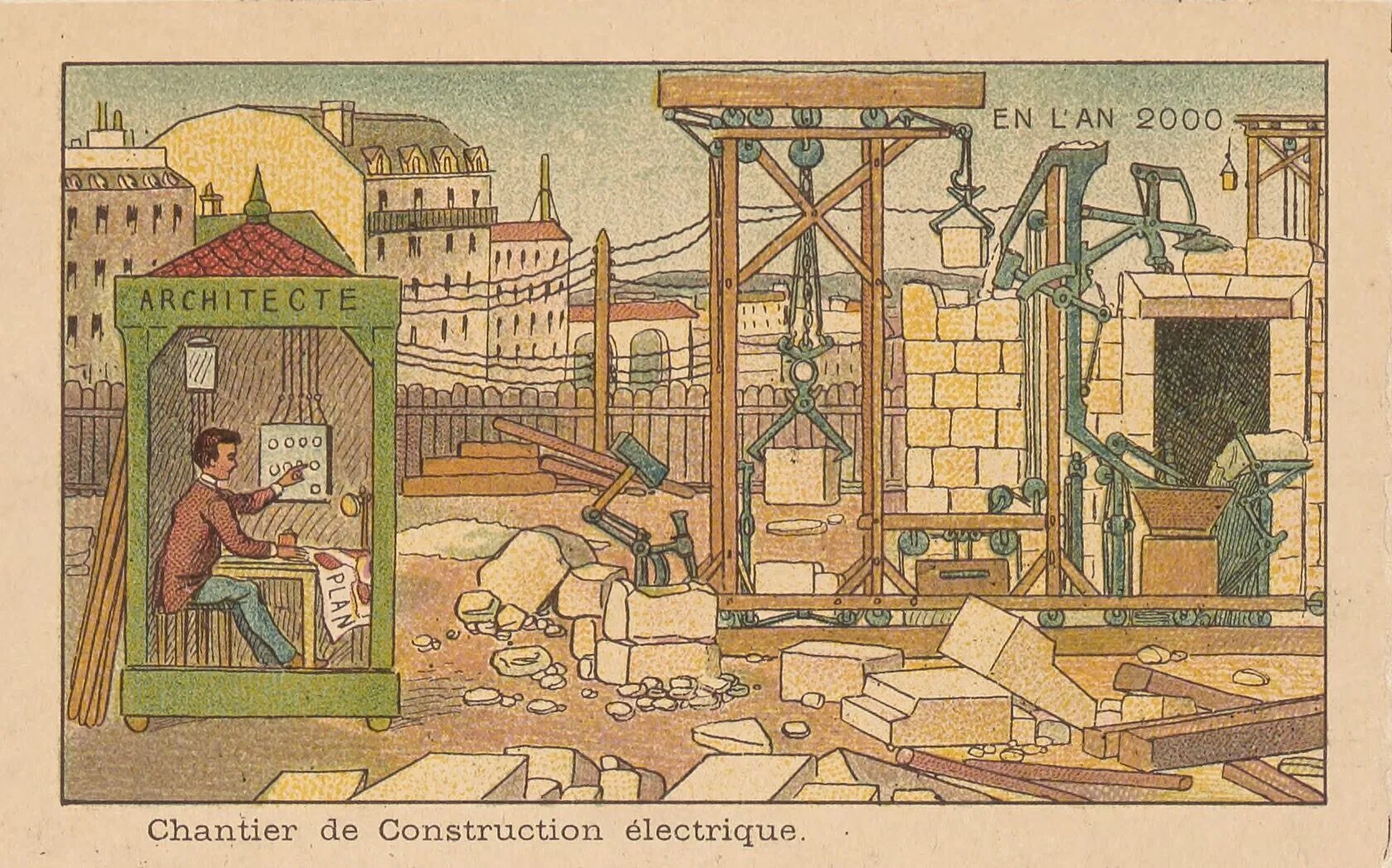

Looking back, it is fascinating to see how human imagination has always envisioned advanced construction. 19th-century artists including Jean-Marc Côté, for example, imagined a “construction site of the future,” full of cranes, scaffolds, and machines. This historical vision connects directly to what we are discussing today: robotics in construction not as a dream, but as a tangible reality.

From the advent of power tools to the use of prefabrication techniques, innovation has continuously reshaped the way construction projects are executed. These days, the AEC/O industry is once again at a turning point, where robotics and automation are emerging as viable solutions to the labor shortage.

Unlike manufacturing, which takes place in controlled environments, construction sites are inherently unstructured and dynamic. This has historically made full automation difficult to achieve. However, advancements in AI and robotics are enabling machines to operate in these complex environments more effectively than ever before.

Rather than replacing workers outright, human-robot collaboration is proving to be the most effective approach. Robotics can take on repetitive, physically demanding, and hazardous tasks, allowing workers to focus on more specialized or supervisory roles. This shift not only improves efficiency and safety but also makes the industry more attractive to younger generations who may be hesitant to enter physically demanding trades.

How Robotics is Changing On-site Productivity

In the present day, the need for construction is obvious. Cities require more housing, kindergartens, schools, universities, airports, and bridges. Yet one of the main barriers remains the high cost of construction and the limited availability of skilled labor.

One of the most significant advantages of robotics in construction is its ability to reduce physical strain on workers. Many construction tasks – such as lifting, carrying, and assembling materials – are physically demanding and can lead to fatigue, injury, or long-term health issues. By introducing robots to handle these repetitive and strenuous tasks, companies can increase worker efficiency while improving safety conditions.

Another key benefit is improved productivity. Robots can perform tasks faster and more consistently than humans, reducing downtime and enabling crews to focus on higher-value work. For example, robotic bricklaying systems can lay thousands of bricks per day with precision, while autonomous equipment can assist in site preparation and surveying, significantly speeding up project timelines.

Additionally, as physical AI continues to evolve, robotic systems are becoming more adaptive to real-world environments. Unlike traditional automation, which relies on pre-programmed routines, AI-driven robotics can analyze and respond to site conditions in real time, making them more effective in complex and unstructured environments.

By integrating robotics into daily operations, construction firms can optimize their workforce, allowing skilled tradespeople to take on supervisory roles while robots handle the heavy lifting – literally. This not only reduces reliance on large labor forces but also helps attract new talent by shifting the perception of construction from purely physical labor to a tech-driven industry with career growth opportunities.

Tackling Material Transport with Robotics

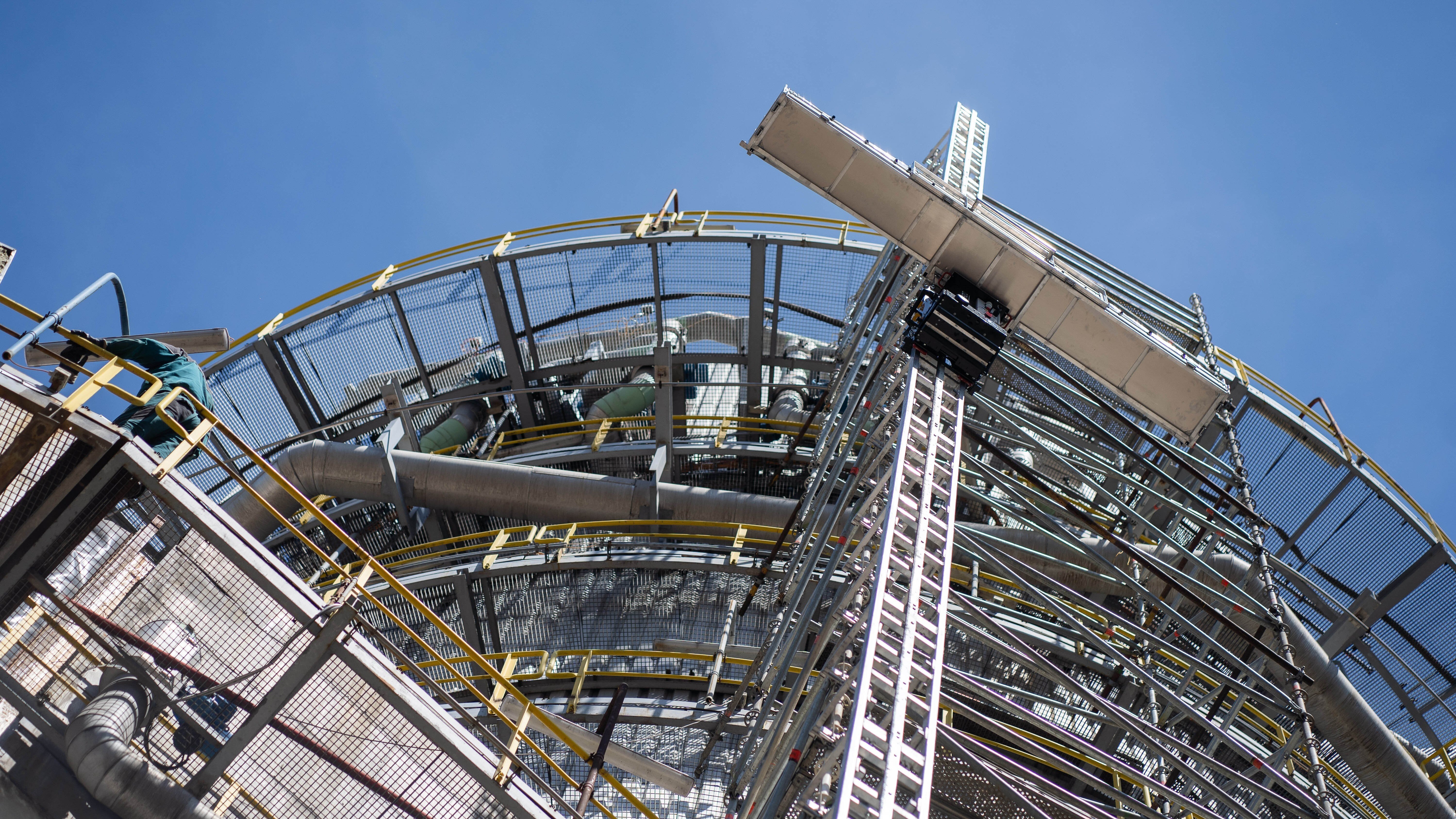

One of the most labor-intensive tasks on construction sites is material transport – moving heavy or bulky materials across different levels of a building. Robotics is making a massive difference here, by streamlining workflows and reducing the number of workers needed for physically demanding transport tasks.

One such example is LIFTBOT, a robotic lifting system developed by Kewazo. Designed to automate vertical material transport, it reduces the reliance on large scaffolding crews by enabling the same job to be completed with just three workers instead of ten. This technology not only addresses labor shortages but also improves safety and efficiency by minimizing manual lifting and reducing the risk of accidents.

Importantly, robotic solutions like LIFTBOT do not replace workers but augment their capabilities, allowing teams to complete tasks faster and with less physical strain. Adaptability is also a crucial factor – construction robots need to be intuitive and easy to integrate into existing workflows to encourage adoption. In this case, LIFTBOT was designed to work alongside human crews, ensuring that skilled workers can focus on more critical tasks rather than spending hours transporting materials.

After witnessing LIFTBOT transporting scaffolding, clients expressed interest in having it handle insulation, tools, paint, mechanical components, and other essential materials, thereby eliminating the bottlenecks caused by inefficient material movement. As solutions like LIFTBOT continue to advance, construction sites are poised to become increasingly automated, enabling companies to complete projects more efficiently while reducing the physical strain on workers.

The Future of Robotics in Construction

The labor shortage in construction is a challenge that won’t resolve itself. As experienced workers retire and fewer young professionals enter the field, companies must explore technological solutions to maintain productivity and stay competitive.

Looking forward, it is clear that human construction alone will not be sufficient to achieve the grand visions often depicted in science fiction: sprawling space stations, colonies on other planets, and massive interplanetary infrastructure. To reach such ambitious goals, construction will inevitably rely on robotics and automated systems, which can scale beyond the limitations of human labor.

So, as robotics technology continues to evolve, its role in construction will expand beyond assisting with specific tasks to transforming the way entire job sites operate. Yet the future isn’t about replacing workers – it’s about enabling them to work smarter.

One key shift will be the transition from physical labor to robot supervision and operation. As automation takes over repetitive and high-risk tasks, workers will take on roles that require oversight, problem-solving, and technical expertise. This evolution could help attract younger generations who may be hesitant to pursue physically demanding careers but are interested in technology-driven roles.

Advancements in AI and machine learning will also make robotics more adaptable, allowing machines to respond dynamically to changing site conditions. As robotic solutions become more affordable and accessible, their integration into daily construction operations will become the norm, helping firms remain competitive while addressing persistent labor shortages.

In a time when workforce challenges and rising costs are putting increasing pressure on construction companies, robotics and automation offer a practical way forward – not by replacing workers, but by augmenting their capabilities. Human-robot collaboration is already improving efficiency, safety, and working conditions, protecting the workforce we already have and making construction a more attractive industry for future generations. With robotics, the AEC/O industry can lay the foundation for a smarter, safer, and more sustainable future, with workers empowered by technology.